Wire Cut EDM Machining Applications

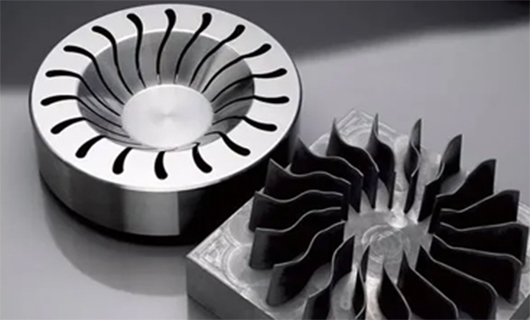

Aerospace Industry

Wire EDM is very useful in the aerospace industry to produce complex shapes such as turbine blades, where high tolerances are required. It is also employed in the production of small nozzles, airframes, and intricate engine components where precision is critical and where the parts have to conform to aerospace specifications.

Medical Industry

In the medical industry, Wire EDM is used to manufacture accurate dental implants, surgical tools, and many other tools. The process is most useful when it comes to manufacturing small parts, for instance in dentistry where the parts are very small and intricate.

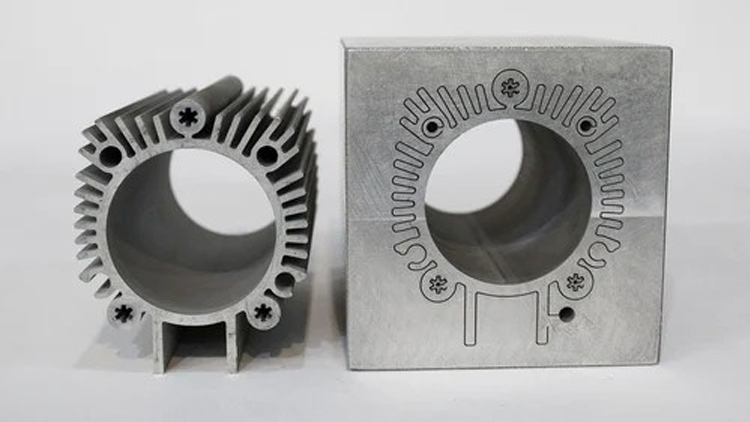

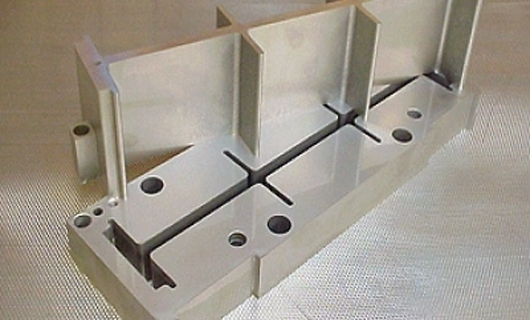

Manufacturing Industry

Wire EDM is widely applicable in the manufacturing of die for plastic injection molding. It guarantees the right contouring of molds which is very important in the production of large quantities of parts with standard quality. Some examples are complex molds for automobile and consumer products.

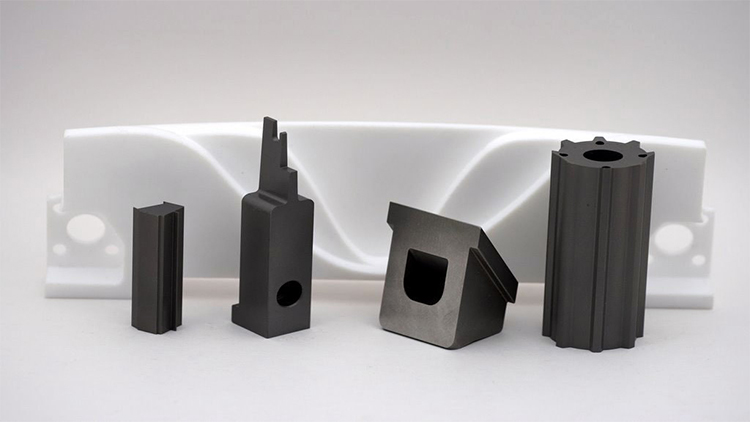

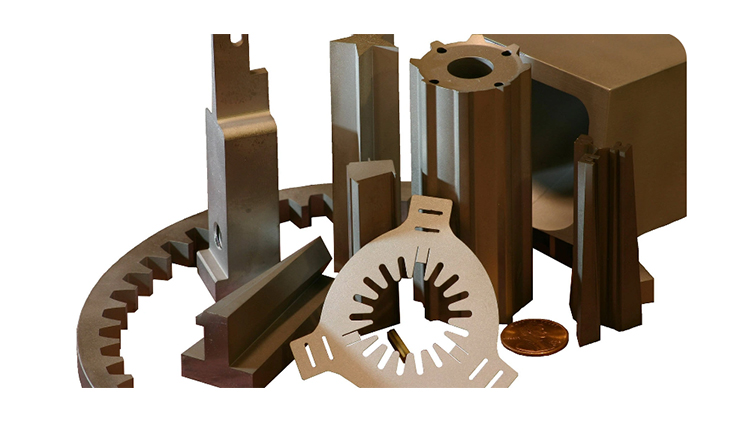

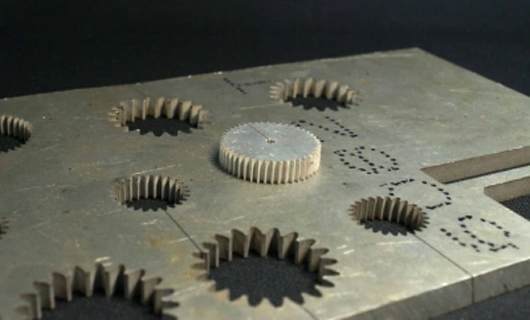

Die & Tooling Industry

Wire EDM is used to create precise components such as punches, dies, cams, gears, and custom die inserts. These parts are essential for high-accuracy stamping and forming operations, ensuring reliable performance in industries like automotive and aerospace.

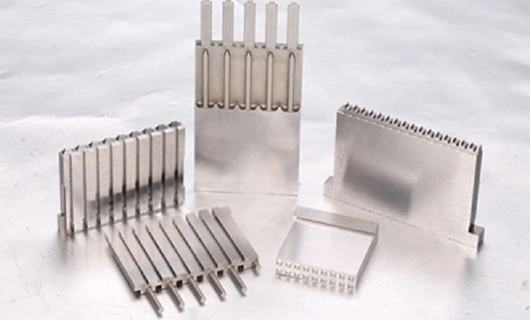

Electronics Industry

Wire EDM is widely used in the electronics industry where small and accurate parts such as connectors, lead frames, and micro parts are manufactured. These parts are used in the internal circuit boards of electronics and even a slight variation in dimensions can hamper the functionality and durability of the device.